Computer Vision in FSM: Automating Equipment Diagnostics with AI-Powered Image Recognition

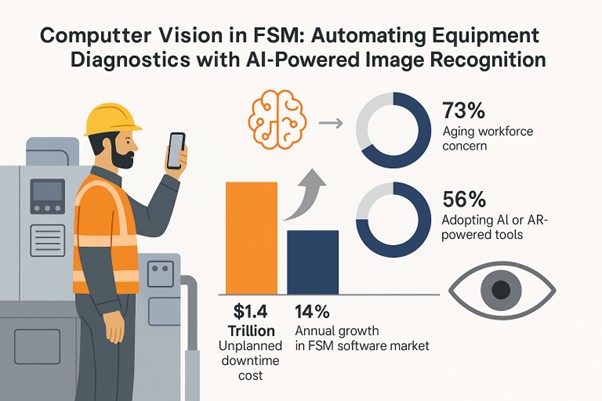

Imagine a field technician arriving on-site and diagnosing a complex piece of equipment within seconds – not by manual inspection, but by simply snapping a photo with a mobile device. This vision is no longer futuristic: it’s the reality of computer vision in FSM (Field Service Management). Unplanned downtime already costs the world’s 500 largest companies about $1.4 trillion annually – roughly 11% of their revenue.

At the same time, FSM leaders grapple with shrinking workforces: 73% of service organizations cite the aging workforce as a critical concern, while 56% are adopting AI or AR-powered tools to bridge these gaps. These pressures are fueling a new urgency to digitize field operations. In fact, the global FSM software market is projected to grow at over 14% annually through 2028. Against this backdrop, companies like FieldEZ are embedding computer vision into their FSM solutions to give technicians “AI-powered eyes,” revolutionising diagnostics and service delivery.

The Role of Computer Vision in Field Service Management

Field service work often hinges on visual assessment: identifying a faulty component, inspecting an installation, or verifying a repair. Traditionally this relied on human expertise and eyesight. Boston Consulting Group highlights that vision AI can instantly identify damaged components and pull up repair instructions—cutting diagnosis times drastically. This tech has matured to the point where modern vision models can detect anomalies or part defects with high accuracy (often more consistently than a human can) and do it in real time.

Another catalyst for computer vision in FSM is the explosion of field data from smartphones, tablets, drones, and even smart AR glasses. These devices serve as the “eyes” for the AI in various environments. No wonder 83% of FSM organizations believe AI will boost customer satisfaction, and 45% plan to deploy AI in the next 2–4 years.

How AI-Powered Image Recognition Automates Equipment Diagnostics

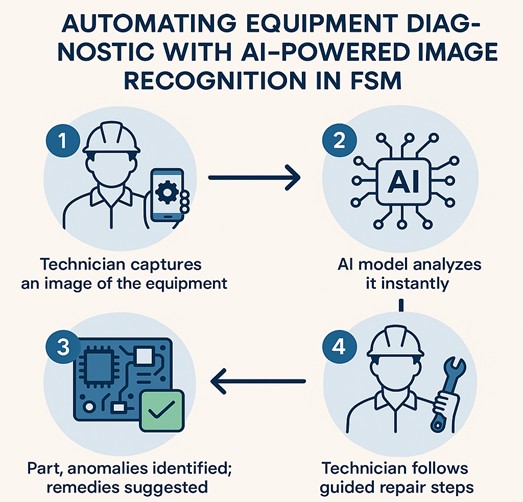

When a technician uses AI-based image recognition, here’s how it typically works in FSM,

- A technician captures an image of the equipment.

- The AI model—trained on thousands of similar machines—analyses it instantly.

- It identifies the part (say, a circuit board), detects anomalies (a burned capacitor), and suggests remedies in real-time while the technician is on site.

- The technician can follow the guided repair steps immediately, without waiting hours (or days) for a specialist to arrive or resorting to trial-and-error.

This dramatically reduces downtime. In utilities, on-site anomaly detection using AI vision has cut diagnostic time significantly and boosted repair outcomes.

Even quality checks become automated: by comparing “before and after” images, AI ensures First-Time Fix success. FSM organizations using such systems report first-time fix rates improving by up to 18%, while AR-assisted image recognition boosts resolution rates by 20–30%.

Benefits of AI-Driven Image Recognition in Field Operations

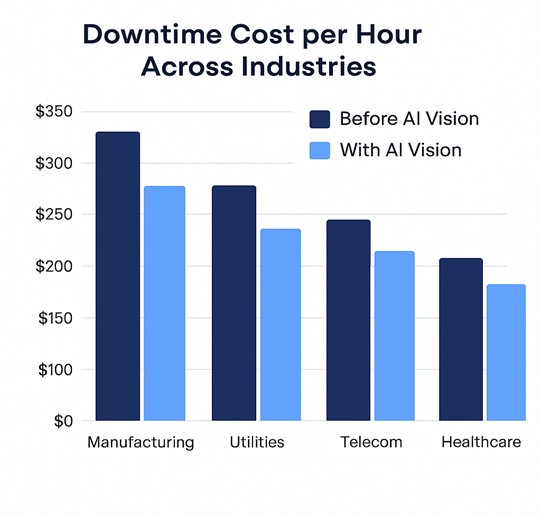

The impact of computer vision on field service KPIs is significant. Below are some of the key benefits of AI-powered image recognition in FSM, backed by industry data:

- Reduced Downtime & Faster Diagnostics

With downtime eating 11% of revenues for industrial giants, even a modest reduction yields huge returns. Vision AI accelerates detection and repair, minimising costly interruptions. - Higher First-Time Fix Rates

Each failed service visit inflates costs. AI guidance equips even junior techs to resolve issues on the first try. Organisations see 18–30% gains in fix rates and customer satisfactio - Increased Safety and Productivity

Once taking an hour, routine checks can now be finished in a matter of minutes. Vision AI lowers human exposure to hazardous areas and increases workforce productivity by 30–40% when used in conjunction with drones for remote inspections.

- Bridging the Skills Divide

AI offers on-demand expertise by integrating veteran knowledge into training data. According to studies, companies that use AI-driven visual assistance save technician training time by 41.

Real-World Applications Across Industries

AI image recognition in FSM is versatile and is being applied across various sectors. Here are a few real-world examples in top industries where computer vision is automating diagnostics and maintenance:

- Utilities and Energy

Power lines, substations, and pipelines are scanned by drones equipped with AI cameras. They identify hazards that previously required risky hand inspections, including as leaks, vegetation encroachment, and cracked insulators. Critical infrastructure downtime and accidents are decreased by this change.

- Industry & Manufacturing

On assembly lines, manufacturing and industrial vision systems detect minute cracks or assembly defects, stopping defective products from moving farther down the line. Due to real-time defect identification, smart factories claim increased throughput and predictive maintenance.

- Telecommunications

AI-powered inspection tools now validate tower, cabling, and data center integrity. Engineers can photograph installations, and the system verifies compliance with schematics. As a result, outage risk has decreased throughout telecom networks and human error has decreased. - Oil & Gas

AI-enabled cameras for oil and gas are utilised on pipelines and offshore rigs to quickly detect leaks, corrosion, and stress areas. By further anticipating failures, predictive analytics reduces catastrophic risks and increases uptime.

Problems with Implementation and Considerations

Despite the significant benefits, it is important to understand that applying AI vision in the field is not an easy task. Organisations face the following real-world challenges:

- High Initial Expenses: The cost of cameras, sensors, and GPUs is high. SMEs need to carefully consider ROI.

- Integration with Legacy Systems: AI integration may be difficult for older FSM systems. This is lessened by vendors like FieldEZ that provide pre-built AI modules.

- Adoption of the Workforce: Technicians may be afraid of being replaced. AI is framed as a helpful tool rather than a threat by effective change management.

- Data & Privacy: Encryption and compliance procedures are required for the safe handling of visual data from client websites.

Future Outlook: Smarter Field Service with FieldEZ

Recognising the potential of computer vision early on, FieldEZ is already working on integrating AI-powered image recognition and augmented reality directly into its FSM platform, with promising outcomes. Instead of flipping through manuals, a tech using FieldEZ can be visually guided step-by-step through a complex repair by an AI that “knows” the equipment. The results speak for themselves: service organizations that leverage such AR and AI visual support tools have reported 20–30% improvements in first-call resolution rates and similar jumps in customer satisfaction.

By enabling FSM leaders to reduce downtime, optimize technician performance, and capture ROI rapidly, FieldEZ exemplifies how vision AI transforms service operations into a strategic advantage. Companies partnering with FieldEZ are equipping their teams with some of the most advanced “smart eyes” in the industry – and gaining a competitive edge through quicker service, higher first-time fix rates, and a more empowered workforce on the ground.

Conclusion!

The message for FSM executives—CEOs, CTOs, and CFOs—is unmistakable: computer vision driven by AI is a strategic necessity rather than merely any technological advancement. The ability to visually direct field repairs and automate equipment diagnostics is resulting in noticeable improvements in customer uptime, cost savings, and service efficiency. Early adopters are already experiencing large decreases in expensive downtime, fewer repeat visits, and speedier solutions.

On the other hand, embracing computer vision in FSM gives your organisation “smart eyes” and predictive capabilities that directly boost the bottom line. Soon, AI will not just diagnose issues but predict failures weeks ahead. This will shift FSM from reactive break-fix to proactive optimisation, giving leaders unprecedented control over uptime and cost efficiency.