Connected Wearables in Field Service: Enhancing Technician Safety and Productivity

Field service operations, globally, depend on millions of technicians operating in frequently challenging environments across a range of industries, including manufacturing, logistics, utilities, and telecommunications. All throughout the world, however, these 2.7 billion frontline workers sustain about a million injuries every day. Companies are expecting ever-higher output all the same. Consider this: OSHA reports that indirect costs can be five times higher than medical bills, and U.S. corporations alone spend almost $1 billion per week on injury-related expenses. There is an urgent need for new tools as a result of the conflict between increased risk and productivity demands.

Wearable technologies – from AR headsets and smart helmets to sensor-laden clothing and exoskeleton suits – are emerging as game-changing components of modern field service management (FSM). By continuously monitoring posture, vitals and context, they alert workers (and supervisors) to hazards before trouble strikes. And by streaming instructions and data directly into technicians’ line of sight, wearables let experts guide fixes remotely, cutting downtime. The result? Companies report significant drop in injury rates (strains and sprains slashed by ~50% and higher output.

In this blog, FieldEZ brings you the importance of Connected Wearables in Field Service and how it enhances technicians’ safety and productivity.

Wearable Safety Nets – Injury Prevention On the Go

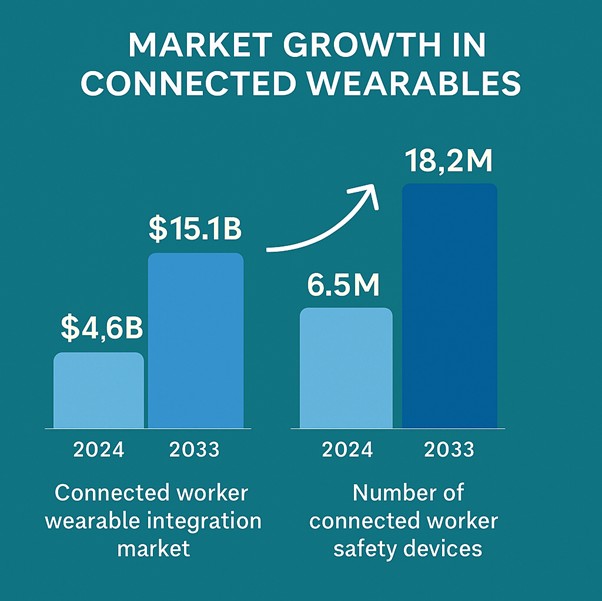

Connected wearables are also becoming massive markets. Research firm Dataintelo values the global “connected worker wearable integration” market at $4.6 billion (2024), projecting it will reach $15.1 billion by 2033 (CAGR ~14%). Imagine a smart vest that buzzes if you stoop dangerously, or a helmet that beeps at toxic fumes. That’s reality now.

Wearables act like 24/7 safety coaches. In one industrial study, strain/sprain injuries fell 49–59% after workers started wearing posture sensors. These gadgets detect “risky” movements – e.g. twisting or bending too far – and vibrate to correct posture in real time. Over months, these retrain habits: workforces report far fewer aches, fatigue and lost workdays.

- For instance, smart wristbands at Fujitsu factories signal heat stress early, and miners’ smart helmets now sense fatigue or gas leaks.

- Likewise, Ford equips assembly-line workers (many over 50) with exoskeleton vests that transfer heavy loads off the body; the older workers report much less fatigue.

These innovations pay off: manufacturers and carriers routinely see 20–40% fewer incidents after adding wearable alerts. (Johnson Controls slashed injuries by ~40% in a year after IoT wearables. In fact, Deloitte projects the overall enterprise wearables market (including AR/VR, exoskeletons and smart watches) to exceed $60 billion by 2022. These numbers reflect one reality: forward-looking organisations are investing heavily in wearables in FSM.

AR Glasses and Voice Tech – Hands-Free Productivity

Smart glasses have quickly become field technicians’ “extra eyes.” In one wind-turbine trial, crews using AR eyewear cut the time for a complex wiring task by 34%. AR lets remote experts actually see the problem alongside the technician: video feeds from the glasses enable instant guidance. For example, Coca-Cola maintenance staff now use AR glasses to share what they see with plant engineers miles away – eliminating travel time and slashing delays. Similarly, at GE Aviation, mechanics wearing AR headsets improved assembly efficiency by roughly 8–12% and reduced errors, because they no longer stop to flip through guides.

Even non-visual wearables help. In digital-first service operations, companies report 10–15% higher technician productivity versus traditional methods. Consider Lufthansa Technik: by equipping mechanics with voice-controlled headsets, a task that used to need two people (one reading manuals, one performing work) is now done by a single technician issuing spoken commands. In effect, one person is doing the work of two, with the wearable headset transcribing progress automatically.

Market Momentum – Everyone’s Betting on Wearables

This isn’t a niche fad – it’s a full-blown industry shift. Analysts forecast the number of worker-safety wearables to nearly triple by 2032 – from roughly 6.5 million today to 18–18.2 million. Major consultancies say field service is a top application domain for wearables. In fact, Market data backs this up: enterprise spending on wearable tech (including AR/VR headsets and exoskeletons) is projected to soar well beyond $60 billion.

- IoT sensors in smart helmets (for gas, vibration or falls),

- Wearables tracking steps and heart rates (to prevent fatigue),

- Biometric bands sensing heat stress all flood into service dashboards. For example, connected hard hats now detect gas leaks and instantly alert supervisors, while posture trackers count exertion to signal breaks – ensuring compliance with safety rules. These data streams let dispatchers see problems before they arise, turning maintenance into proactive, not reactive, work.

As BCG’s Field Service AI program puts it: “Remote support – enhanced by wearable devices that display information in the user’s field of view – provides guidance” to technicians.

- In logistics and field delivery, smart band technology or smart shoes detect risky posture – one industrial study found strain injuries dropped by ~50% in facilities that gave employees posture-monitoring wearables. In extreme environments, the benefits are even more dramatic: Fujitsu’s factory uses wrist-wearables to issue early warnings of heat-stress, and mining crews wear sensor helmets to detect fatigue or gas hazards.

The result is higher first-time-fix rates, more jobs closed per day, and lower labor costs – exactly the metrics every CEO and CTO tracks.

Case Studies: Wearables in Action

Across industries, pilots and programs are proving the value of wearables in the field. For example:

- Energy & Utilities. TotalEnergies equips field crews at refineries with AR smart glasses (RealWear headsets) that stream schematics and live expert help into the worker’s view. (Bonus: less travel for experts, cutting CO₂ emissions too.)

- Mitsubishi Electric’s maintenance teams use head-mounted AR (via TeamViewer) to collaborate with remote engineers.

- Logistics & Warehousing. DHL’s distribution centres have tested “vision picking” with smart glasses. In one Dutch pilot program, pickers wearing AR glasses saw on-screen prompts for each order, boosting picking efficiency by 25% and reducing errors.

- Even Lockheed Martin’s factory floor uses AR. Its mechanics wear smart glasses during assembly, receiving digital work orders and diagrams in real time.

- Oil & Gas. Drilling and pipeline crews wear connected helmets and wristbands that detect toxic gas levels, heat or fatigue. In practice, these trigger beeps and alerts when conditions turn dangerous – and OSHA notes that such early warnings drastically cut incident rates.

- Telecom & Construction. Tower climbers carry wearables too: GPS trackers and fall-protection vests linked to dispatch, plus panic buttons. If a technician slips or an outage occurs, alerts automatically ping the control center. This real-time safety network (like FieldEZ’s own solution on towers) vastly improves accountability and response.

- Healthcare Equipment. Technicians wearing AR glasses or belt-mounted tablets can log parts or pull schematics without leaving the exam room.

Companies using wearables consistently report strong KPIs: higher first-time fix rates, faster response times and lower costs – all credited to having the right data at the right time.

FieldEZ and the Connected Future

Leading FSM platforms are racing to bake wearable data into their suites. FieldEZ, for instance, envisions its ServiceEZ software consuming IoT alerts from workers’ gear. As FieldEZ puts it, IoT-and-AI tools now let you “see problems before they arise,” turning maintenance truly predictive. Early adopters of such systems report exactly the expected benefits: more efficient resource use, better compliance and clear productivity gains. When wearables talk directly to scheduling and analytics dashboards, dispatch managers see real-time field conditions – every worker’s location, status and safety alerts – in one pane.

Conclusion!

Connected wearables are no longer a glimpse of the future—they’re the new standard for how modern field service is executed. The message to industry leaders is clear: this is not a technological luxury—it’s a strategic imperative. Forward-thinking CEOs and CTOs who embed wearables into their FSM ecosystems today are laying the foundation for predictive, agile, and resilient operations tomorrow.

From AR glasses that reduce repair time by double digits to biometric vests that detect risks before they escalate, the results aren’t just impressive—they’re transformational. This is your opportunity to lead from the front. To not just respond to change, but drive it.